Bamboo Scaffolding: What It Is and Why It’s Still Relevant Today

Bamboo is one of nature’s most remarkable materials, prized for its strength, flexibility, and sustainability. It has been used for centuries in everything from furniture and flooring to textiles and construction.

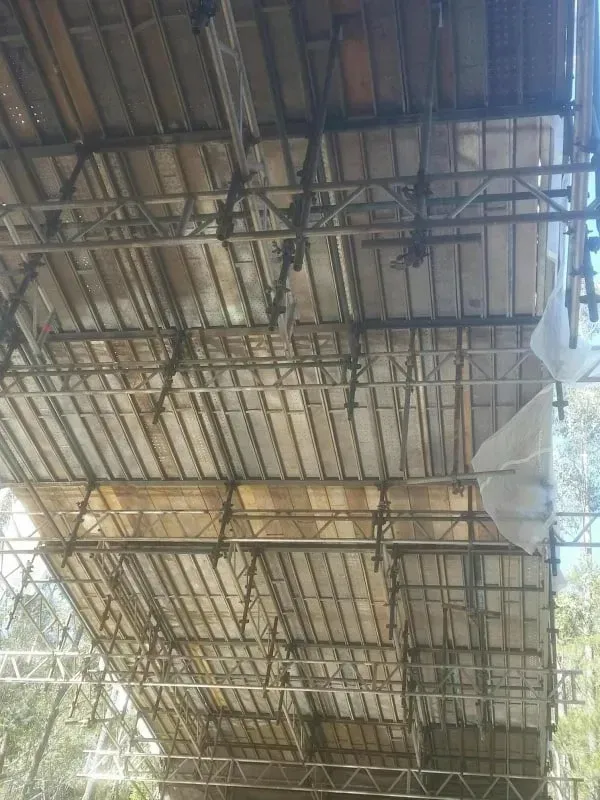

Bamboo scaffolding is a centuries-old construction technique where bamboo poles are tied together to create a strong, flexible framework for construction projects. It has been used in building construction in Hong Kong and southern China, where skilled bamboo scaffolders can erect bamboo scaffolding within hours. They use ancient techniques that have been passed down for generations.

Bamboo is known for its natural durability and ability to adapt to various architectural designs making it a truly versatile choice in the industry. But does this traditional method still have a place in today’s modern construction landscape?

Is Bamboo Scaffolding Still Used Today?

Despite modernisation, bamboo scaffolding remains a trusted construction method in Hong Kong. Its continued use is driven by the affordability of the material and the expertise of skilled workers who have mastered the proper knot-tying techniques needed to secure towering bamboo structures. Most of the time, bamboo scaffolders worked at heights with minimal safety gear. Though it is a dangerous job, they are highly respected for their craft. Bamboo scaffolding is widely used in for constructing and maintaining skyscrapers.

Types of Bamboo Used

In Hong Kong, two primary types of bamboo are utilised:

- Kao Jue (Pole Bamboo): Used for both vertical and horizontal constructions, with an external diameter of no less than 40mm.

- Mao Jue (Hair Bamboo): Primarily used for vertical and diagonal structures, with a minimum diameter of 75mm and a thickness of at least 10mm.

As regulations evolve and materials change, Hong Kong may see a gradual shift toward steel scaffolding, but for now, bamboo scaffolding remains a reliable and sustainable option.

In mainland China, regulations have tightened, banning bamboo scaffolding for buildings over six stories due to safety concerns and structural limitations at higher elevations. However, despite this restriction, bamboo scaffolding is still widely used in smaller-scale projects, where it remains a popular choice for its affordability and ease of use.

What Makes Bamboo an Ideal Material for Scaffolding?

Several key factors contribute to its continued use:

1. Strength and Durability

Bamboo has impressive tensile strength, comparable to steel, allowing it to support heavy loads without breaking. When properly arranged, bamboo scaffolding creates sturdy and stable structures capable of handling demanding construction tasks. Additionally, bamboo’s natural fibres distribute weight evenly, enhancing its overall durability.

2. Lightweight Nature

One of the biggest advantages of bamboo scaffolding is its lightweight nature. They are easy to carry, transport, and assemble, making construction work more efficient. Workers can quickly erect and dismantle scaffolding with minimal machinery, reducing both labour costs and time spent on-site.

3. Cost-Effectiveness

Compared to other scaffolding materials, bamboo is an economical option. Since it is widely available and grows abundantly in many regions, its cost remains lower than that of steel or aluminium. Additionally, bamboo can be reused multiple times before needing replacement, further reducing expenses for construction companies.

4. Eco-Friendly Material

As a rapidly renewable resource, bamboo is one of the most sustainable materials used in construction. It grows significantly faster than hardwood trees, often reaching maturity in just a few years. This makes bamboo scaffolding an environmentally friendly alternative, helping reduce deforestation and carbon footprints in the building industry. Furthermore, at the end of its lifespan, bamboo can decompose naturally, leaving minimal waste, which requires energy-intensive recycling processes.

The Other Uses of Bamboo Scaffolding

Though primarily used in construction projects, bamboo scaffolding plays a significant role in other industries as well:

Bamboo Theatres

Traditional bamboo theatres are still built for cultural performances and festivals, especially in regions where bamboo craftsmanship is a long-standing tradition. In Hong Kong, for example, bamboo theatres are an essential part of Cantonese opera performances, providing a temporary yet sturdy stage for these events. The scaffolding framework allows for large-scale, open-air venues that can accommodate hundreds of spectators. Despite their temporary nature, these theatres are designed with great precision to ensure stability and safety.

Event and Exhibition Structures

Bamboo scaffolding is commonly used for building temporary stages, pavilions, and exhibition halls. Many large-scale events, such as trade fairs, music festivals, and public celebrations, incorporate bamboo into their structures due to its adaptability and ease of setup. Unlike permanent venues, the entire structures can be assembled quickly, providing organisers with an efficient and sustainable solution for temporary installations.

Cultural and Religious Installations

In many parts of Asia, large decorative installations for religious or cultural festivals rely on bamboo structures for temporary displays. These include temporary temples, ceremonial gateways, and elaborate festive decorations. For instance, in Macau, bamboo scaffolding is used to construct temporary temples during religious celebrations to honour deities and bless sailors. Similarly, in India and Nepal, bamboo is frequently used to build grand structures for Hindu and Buddhist festivals, such as Durga Puja and Bisket Jatra. These installations require a lightweight yet sturdy framework, making bamboo the preferred material.

Beyond construction, bamboo scaffolding continues to be a versatile and culturally significant material, proving its value in various industries that rely on temporary yet strong and sustainable structures.

Challenges and Limitations of Bamboo Scaffolding

Despite its many benefits, bamboo scaffolding presents challenges that must be managed to ensure safety and durability.

1. Weather Susceptibility

Bamboo is more vulnerable to weather conditions than metal scaffolding. Prolonged exposure to moisture can

cause it to weaken, rot, or develop mould. In humid or rainy environments, regular maintenance and treatment are essential to prevent deterioration. Extreme heat can also dry out bamboo, making it brittle and more likely to crack. To extend its lifespan, workers apply protective coatings and store bamboo properly before use.

2. Skill-Intensive Construction

Building bamboo scaffolding requires specialised skills. Workers must securely tie bamboo poles using nylon straps or metal wires in a process called "lashing." These ties are crucial for stability, and if done incorrectly, the structure can become weak and unsafe. Since this technique is traditionally passed down through generations, fewer young workers are learning the trade.

The decline in trained professionals means that construction companies often prioritise modern scaffolding solutions that require less manual expertise. For example, businesses looking for safe and reliable scaffolding options may turn to scaffold hire services, which provide high-quality, pre-assembled scaffolding systems that meet strict safety regulations. These alternatives are easier to set up, require less specialised training, and comply with modern construction standards.

3. Material Inconsistency

Unlike steel, bamboo is a natural material, meaning its quality varies. Factors such as species, age, and treatment affect its strength and durability. If not properly selected and dried, bamboo may split or bend under heavy loads. Construction companies must thoroughly inspect and test bamboo poles to ensure they meet safety standards before use.

Ensuring Safety in Scaffolding

Safety in construction is essential, as improper assembly or use of scaffolding can lead to serious accidents. To minimise risks, strict scaffolding safety practices must be followed to protect workers and maintain structural stability.

In Australia, all scaffolding must comply with Scaffolding Australian Standards, which set essential safety requirements for construction sites, ensuring scaffolding is built and maintained correctly.

Why Bamboo Scaffolding Hasn’t Found Its Place in Australia

Despite its numerous benefits, bamboo scaffolding is not commonly used in Australia. One of the main reasons is material availability — bamboo does not grow abundantly in Australia as it does in Asia, making it a less practical and cost-effective option for local projects. The reliance on imported bamboo would increase costs and logistical challenges, reducing its appeal compared to readily available materials like steel and aluminium.

Another major factor is safety standards. Australia has strict regulations governing construction materials and methods to ensure worker safety and structural integrity. Unlike engineered materials that undergo rigorous testing, bamboo's unpredictable nature makes it difficult to regulate for large-scale projects.

Additionally, structural consistency is a key concern. Australian builders favour materials with uniform profiles and predictable performance, which are essential for maintaining safety and efficiency in modern construction.

Key Takeaway

While bamboo scaffolding remains relevant in certain countries in Asia, materials like steel and aluminium dominate modern construction due to their superior strength, durability, and resistance to fire and corrosion. Steel is known for its load-bearing capacity and long-term reliability, while aluminium offers the advantage of being lightweight and easy to handle. These materials ensure compliance with strict safety standards and provide the consistency required for large-scale projects.

Based in Wollongong, Crewscaff provides scaffolding solutions for residential, commercial and industrial projects. We have knowledge of all aspects of scaffolding, from reading and interpreting plans, designing scaffolds, running crews, communicating with builders, and giving the customer exactly what they want with zero headaches.

CONTACT INFORMATION

Unit 3/30 Sunset Ave, Barrack Heights NSW 2528

Wollongong / Illawarra Area

Phone: 0452 177 483

Opening Hours: 7am - 5pm

ABN:

35 167 958 321

ACN:

167 958 321