Top 10 Construction Site Hazards to Look Out For

Construction site hazards are not only dangerous for workers, but they can also pose risks to bystanders and people in neighbouring areas. In work-related statistics conducted by Safe Work Australia, it was found that 17 out of an estimated 160 fatalities in 2021 were from construction sites.

With this number of fatalities in the construction industry, employers, workers, and everyone involved in construction must be aware of the potential hazards that may exist in the workplace to help prevent injuries and possible deaths from taking place in the future.

What are the physical hazards at the construction site?

Construction site hazards come in different forms, but they all have the potential to cause harm and injury. Depending on the type of construction work being done, some of the most common hazards in the construction industry may be one of the following:

1. Working at height

Among the primary causes of occupational illnesses and accidents in construction sites involve falls from heights which account for approximately a quarter of worker fatalities annually, making it the leading cause of fatal injuries.

To address this issue, it is important that comprehensive training be provided to all employees engaged in tasks at elevated levels. This training should cover the safe practices associated with various equipment and surfaces, such as scaffolding, ladders, and roofs. To ensure stability and safety, scaffolding on job sites should be designed, erected and dismantled only by a reputable scaffolding hire Wollongong provider.

According to the law, all employers are required to evaluate the risks associated with working at heights. They must create a plan to guarantee that all work is done safely and ensure that all workers have the appropriate training and safety procedures to take in order to work effectively at heights.

To ensure the safety of workers, working at height necessitates careful planning, supervision, and adherence to specific approaches and precautions. Here are some recommended measures:

- Avoid working at height as much as possible. If a task can be completed at ground level, do so to minimise risk and limit the amount of time workers need to be exposed.

- Utilise equipment safely to mitigate the risk of fatal falls. For instance, opt for scaffolding with a double guard-rail system to ensure that you are provided with an additional layer of protection.

- Reduce the potential impact of a fall by providing a safety net for to catch and safeguard workers in the event of a fall.

By incorporating these strategies, we can actively promote the well-being of construction workers and minimise the site hazards associated with working at height.

2. Moving objects

Construction projects in construction sites are subject to ever-changing conditions where hazards increase as work progresses. One of these hazards can involve moving objects.

Moving objects such as overhead lifting equipment, excavators, supply vehicles, and everything that can move around uneven terrain can pose serious injuries and even risks of death to construction workers on the job.

Such construction site hazards can be mitigated by ensuring workers do the following:

- Maintain a safe distance from moving objects and avoid working near them whenever possible.

- Be attentive and aware of your surroundings, particularly when dealing with objects that lack warning lights or audible signals.

- Wear appropriate personal protective equipment (PPE), such as a high-visibility jacket, to ensure that you are easily seen by others in the vicinity.

3. Slips, trips, and falls

Slips, trips, and falls are prevalent almost anywhere. Given the nature of construction sites which often involve unused materials all over the ground and working on uneven terrains, it is no surprise why such construction site hazards are so common.

Every year, several construction workers sustain injuries because of slips, trips, and falls. Fortunately, these could be avoided by effectively managing working areas and keeping them free from debris and other hazardous materials. Some of these may include:

Uneven terrain or uneven surfaces

Risks and hazards can be prevented by providing designated walkways with good footing and ample lighting. By ensuring the worksite is well-lit, you can help workers see any potential hazards in the area.

Obstacles

Slips, trips, and falls can be avoided by providing workers with work and storage areas and designating specific zones for waste management and collection.

Trailing cables

Tripping over trailing cables is common if the cables are not managed. If possible, use cordless tools and equipment to minimise risk involving slips, trips, and falls. If this is not possible, use cable guards and cable covers to protect cords from foot traffic.

Wet and slippery surfaces

Slippery surfaces caused by mud can be treated with stone, while grit is recommended if it was caused by ice. Additionally, signposting any slippery areas and wearing footwear with a firm grip can help prevent slips and falls.

4. Noise

Construction sites are inherently noisy environments - making noise a prevalent hazard in the construction industry. Since most tools in the construction site produce high noise levels, prolonged exposure to loud, repetitive, and excessive noise may lead to temporary or permanent hearing loss or tinnitus (ringing in the ears). Moreover, noise can be a dangerous distraction, diverting workers' attention from their tasks and increasing the likelihood of accidents.

This is why employers should implement a comprehensive noise risk assessment and provide hearing protection devices like earplugs and earmuffs to protect workers from the risks of hearing loss due to prolonged noise exposure in their work environment.

5. Hand-arm vibration syndrome

Hand-arm vibration syndrome (HAVS) is a condition that affects the blood vessels, nerves, and joints in the hand and arm. It commonly results from prolonged use of hand-held power tools, ground working equipment, and vibratory power tools that all produce vibrations.

Although HAVS can be prevented, it can cause permanent damage to the person who is affected. Common symptoms include numbness and tingling in the hands, aching or loss of strength, decreased grip strength, cold intolerance and whiteness of the fingers.

Managing and evaluating hazards related to working with vibrating equipment and machinery on the construction site is critical. Workers should be given appropriate protection gears while using vibratory power tools, and equipment must be well-maintained to prevent harm.

6. Material and manual handling

In construction, it is common for materials and equipment to be lifted and moved around during the construction process. Regardless of the size and weight of the load, there are two main ways to carry out this task - through manual handling or with the use of equipment.

When manual handling is involved in job tasks, relevant training must be provided. If a worker needs to use lifting equipment, he should be given adequate training regarding safe manual handling and its proper usage. A test should also be taken to assess their ability to operate the equipment safely.

7. Collapsing trenches

Trenching and excavations are construction hazards that go hand in hand with the construction process. They can be difficult to work around, especially due to their potential to cause injury, harm, or even death if not managed properly.

If a building site is being demolished, it tends to collapse without notice. To avoid such hazardous occurrences in construction sites, construction companies must see to it that engineering control measures are applied before the project starts. For trenches, site managers must:

- Consider the appropriate support for the trench.

- Ensure that the trench is completely secured.

- Conduct regular trench inspections before and during work shifts.

- Take extra precautions when workers handle heavy objects near trenches. Suitable protective equipment and gear like hard hats should be provided.

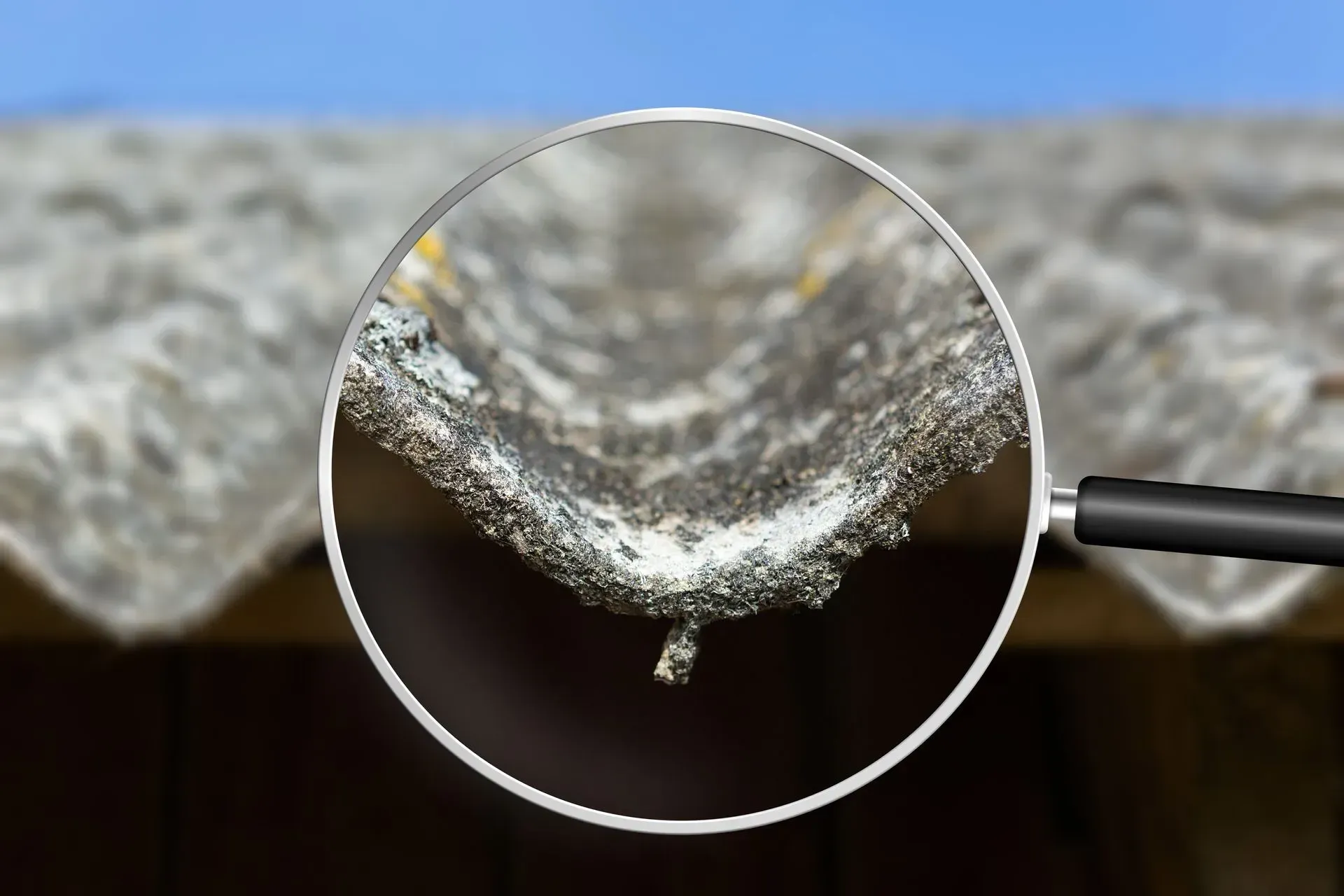

8. Asbestos

Asbestos is known for having great fibre strength and heat resistance. However, despite its desirable properties, it poses hazards and significant risks to human health, causing diseases such as asbestosis, mesothelioma, and lung cancer.

Despite the hazards and risks associated with it, asbestos is still used in most construction projects. To further protect people from asbestos, employers must inform their workers where asbestos is present and train them on how to handle suspicious materials that may contain asbestos.

9. Electricity

Electrical hazards are a prevalent safety concern in the construction industry, with about 24% of all electrical shock notifications reported from the industry between 2021 and 2022. Whether a construction worker comes in contact with live wires directly or indirectly through an electrical conductor, he can suffer serious injury or death from an electrical shock.

Most electrical hazards and accidents occur due to contact with overhead power lines, underground power cables, electrical equipment, or machinery. Electric shocks, resulting from such contact or usage, often lead to falls from ladders, scaffolds, and other work platforms.

What's also alarming is the growing number of electrocutions among workers who are not qualified electricians but are involved in performing electrical work on construction sites.

10. Airborne fibres and materials

Construction sites produce a lot of dust which is often made of very fine particles and may be composed of a toxic mixture from the fibres of hazardous materials. Due to their particle size, these dust particles can travel easily through the air and get deposited on surfaces, including people’s skin and in their lungs. Prolonged exposure to dust on construction sites can sometimes lead to lung damage and other diseases such as chronic obstructive pulmonary disease, asthma, and silicosis.

To prevent such construction hazards, employers should provide each construction worker with personal protective equipment including a dust mask and eye protection to limit the amount of airborne fibres entering the body. Furthermore, construction sites should be adequately ventilated, and materials must be dampened prior to use.

What are the risks on a construction site?

Construction sites produce a lot of dust which is often made of very fine particles and may be composed of a toxic mixture from the fibres of hazardous materials. Due to their particle size, these dust particles can travel easily through the air and get deposited on surfaces, including people’s skin and in their lungs. Prolonged exposure to dust on construction sites can sometimes lead to lung damage and other diseases such as chronic obstructive pulmonary disease, asthma, and silicosis.

To prevent such construction hazards, employers should provide each construction worker with personal protective equipment including a dust mask and eye protection to limit the amount of airborne fibres entering the body. Furthermore, construction sites should be adequately ventilated, and materials must be dampened prior to use.

How do you assess risk on a construction site?

Risk assessments in construction involve identifying, analysing, and evaluating potential hazards and risks associated with construction activities, sites, or projects to ensure the safety of workers, visitors, and members of the public who might be affected by the construction project. These involve examining the construction site, materials, equipment, and processes involved in the project, identifying potential hazards, and developing strategies to control, manage, or mitigate those risks.

Risk assessment in construction involves the following steps:

1. Identify hazards.

This step involves determining hazards that could cause harm.

2. Assess the risks.

Evaluate potential risks as needed by understanding the nature and severity of harm that may result from the hazard, and the likelihood of it happening. This step may not be necessary if the risk is already known and appropriate controls are in place.

3. Control the risks.

Implement control measures that can be realistically done under the circumstances. Examples of risk control measures include engineering controls, administrative controls, and safety equipment.

4. Record your findings.

New paragraph

Keep a record of the risk assessment results, including any control measures taken. Be sure to document any changes made in the process as well.

5. Review the controls.

Review the risks, hazards, and controls regularly and update as necessary to make sure they are operating as intended.

Larger construction work and those in sectors where workers are exposed to more or higher risks are likely to need more complex, sophisticated risk management processes.

Takeaway

Construction sites are highly dangerous environments that require workers and site managers to take all necessary precautions to reduce construction hazards. Among these, falls are the primary reason for fatal accidents and the third leading cause of injury.

To reduce the risk of falls, scaffolds are often used as a temporary working platform for workers to access different heights and areas. Aside from this, it's crucial to provide workers with proper training and safety gears to keep them aware of their surroundings and any potential risks. By taking all necessary safety precautions, such as hiring high-quality scaffolds and providing protective equipment and adequate training, workers can significantly reduce hazards in construction sites.

At Crewscaff, we are a fully insured scaffolding for hire company that prioritises safety above all else. We have all required insurances and all our staff adhere to the standards set by the 'Scaffolding & Scaffolding Work Code of Practice' in compliance with WHS regulations. Trust us to provide reliable and safe scaffolding solutions tailored to your specific project needs. Call us today for a free quote.